Machining Services for the Automotive Industry

How our CNC machine shop supports the automotive industry

The automotive industry is built on precision, reliability, and efficiency—and a CNC machine shop is at the heart of making that possible. From producing high-performance engine components to manufacturing intricate safety-critical parts, CNC machining ensures automakers can deliver vehicles that meet strict quality standards while keeping up with production demands.

The role of CNC machining in the automotive industry

CNC (computer numerical control) machining uses advanced, computer-driven tools to produce parts with exceptional accuracy and repeatability. In the automotive sector, this technology is essential for:

-

Prototyping — turning initial designs into functional test components quickly and cost-effectively.

-

High-volume production — manufacturing thousands of identical parts with consistent quality.

-

Custom solutions — producing specialized components for unique vehicle models or performance upgrades.

By leveraging CNC capabilities, automakers can shorten lead times, reduce waste, and maintain the tight tolerances required for modern vehicles.

Common automotive components made in CNC machine shops

Machine shops produce a wide variety of parts for the automotive industry, including:

-

Engine parts — cylinder heads, engine blocks, pistons, camshafts, crankshafts, and connecting rods.

-

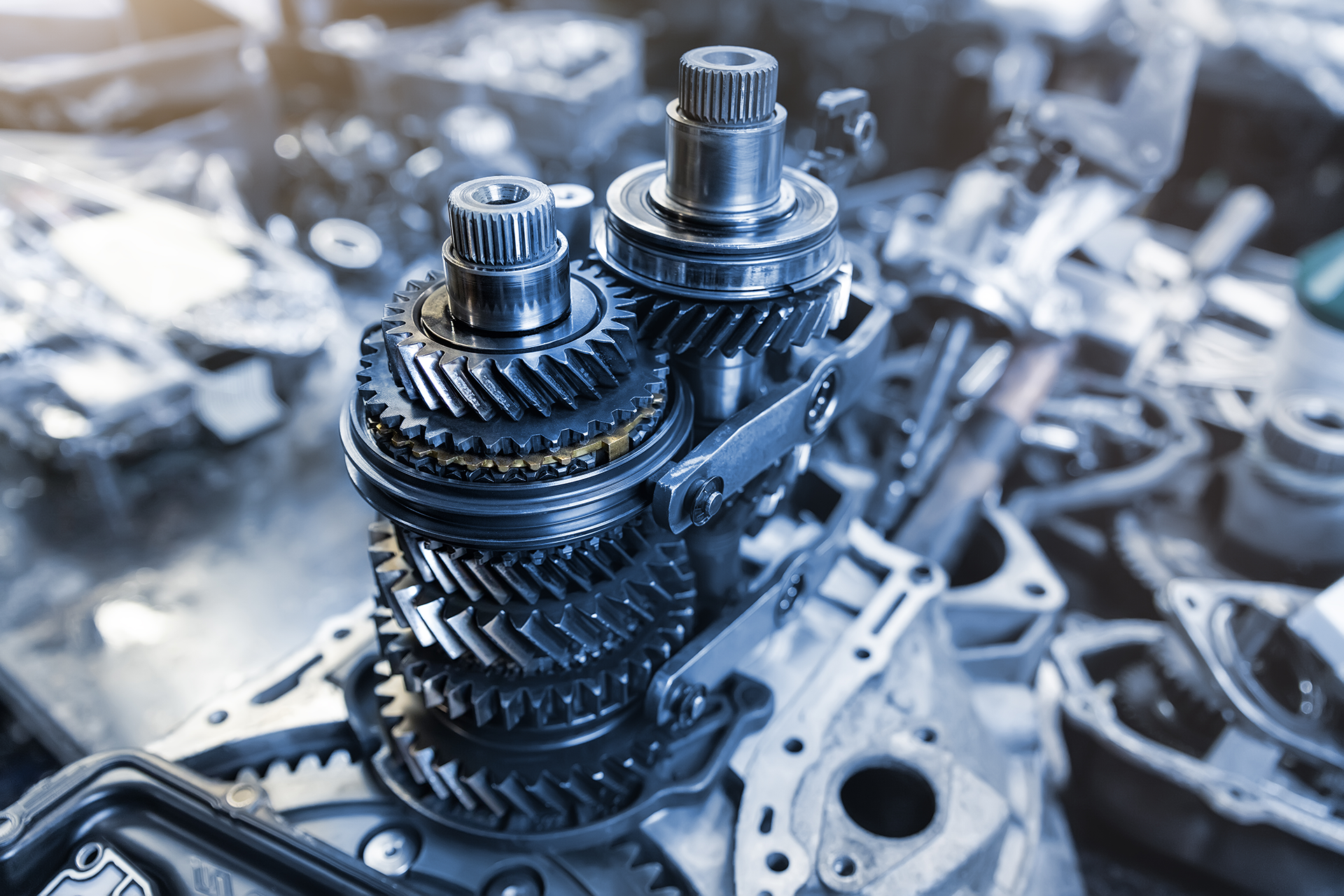

Transmission components — gears, shafts, and housings designed for both manual and automatic systems.

-

Suspension and steering parts — control arms, knuckles, steering columns, and brackets.

-

Brake system components — calipers, rotors, and brackets for both conventional and performance braking systems.

-

Custom fixtures and molds — specialized tools and jigs that streamline assembly processes.

These components demand not only high precision but also material expertise to ensure they withstand heat, stress, and wear over a vehicle’s lifetime.

Common challenges faced by automakers

The automotive industry operates in a fast-paced, competitive environment. Automakers must balance speed, cost, and quality while dealing with:

-

Tight production deadlines — vehicle launches and model refreshes leave little room for delays.

-

Stringent quality standards — safety regulations and consumer expectations require flawless components.

-

Material and supply chain fluctuations — sourcing high-quality raw materials can be unpredictable.

-

Technological advancements — staying competitive means adapting to new manufacturing technologies quickly.

A single defective part or supply delay can disrupt entire production lines, making supplier reliability critical.

Why choosing the right manufacturing partner matters

Selecting the right CNC machine shop can mean the difference between smooth operations and costly setbacks. A trusted manufacturing partner should provide:

-

Proven experience in automotive machining with a portfolio of successful projects.

-

Commitment to quality control with inspection processes, certifications, and traceability.

-

Capacity for both prototyping and large-scale production to support growth and innovation.

-

Responsive communication to quickly address design changes or production challenges.

By partnering with a skilled, well-equipped CNC machine shop, automakers can ensure their components are built to exact specifications, delivered on time, and ready to perform.

Learn more

Ready to partner with a CNC machine shop that understands the demands of the automotive industry? Our team combines precision machining expertise with a commitment to quality, reliability, and on-time delivery.

Whether you need prototypes, high-volume production, or specialized components, we’re here to help you keep your production line moving and your customers satisfied.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Location:

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003