Basin Precision Machining is now Wenzel Industries

Read the full story »

Our time is now

As the global economy evolves, you cannot afford to rely on international vendors. Businesses that fail to pivot are quickly falling behind. Luckily, your high-quality, cost-effective precision machining solution can be found in your backyard.

Basin Precision Machining is a Wisconsin-based CNC machining company with the automated equipment, experience and world-class manufacturing processes to compete with any contract machine shop.

Innovative, agile companies see change as an opportunity. It’s been decades since a moment like this has come along. Are you ready to seize it?

World-class Midwest manufacturing

- State-of-the-art equipment.

- Factory-wide single piece flow operation. Completely cellular.

- Broad flexibility in size, configuration, and complexity.

- Extensive experience with all materials.

- Class leading process. methodology and innovation.

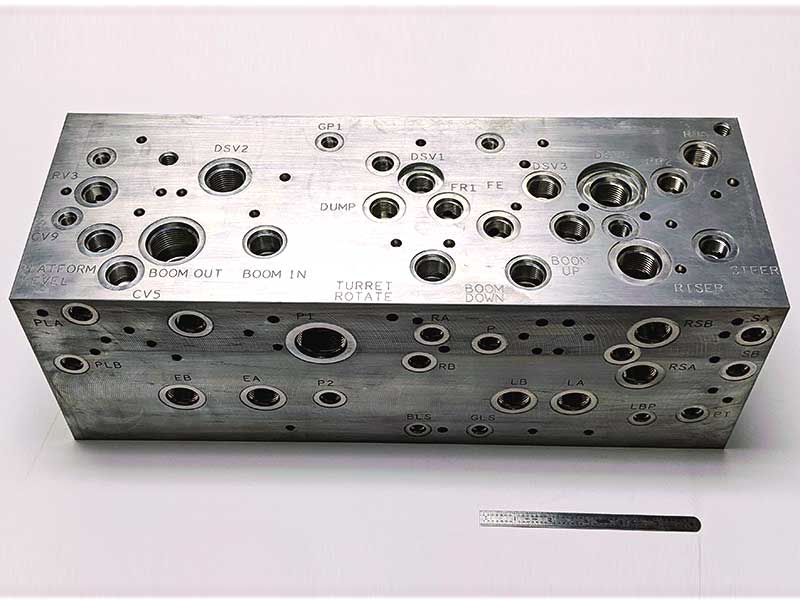

- Extensive knowledge of hydraulic manifold production and fluid power.

- Continuous improvement and lean manufacturing methodologies.

- SPC analysis of our processes.

- Over 100 dedicated, well trained team members.

Your Solutions

Who We Are

We are a provider of high volume, tight tolerance machined components and assemblies, run on a lean, just-in-time basis. We have been meeting the needs of high-profile industrial OEM manufacturers since 1980, providing uncompromising quality for the most stringent requirements.

Our production processes use the latest proven technologies in CNC machine tools, inspection equipment, cutting tools and communications to eliminate waste, control variation and create a product of reliable quality.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003