Precision Machining for Electronics and High-Tech Equipment

Precision machining for high-tech electronics hardware

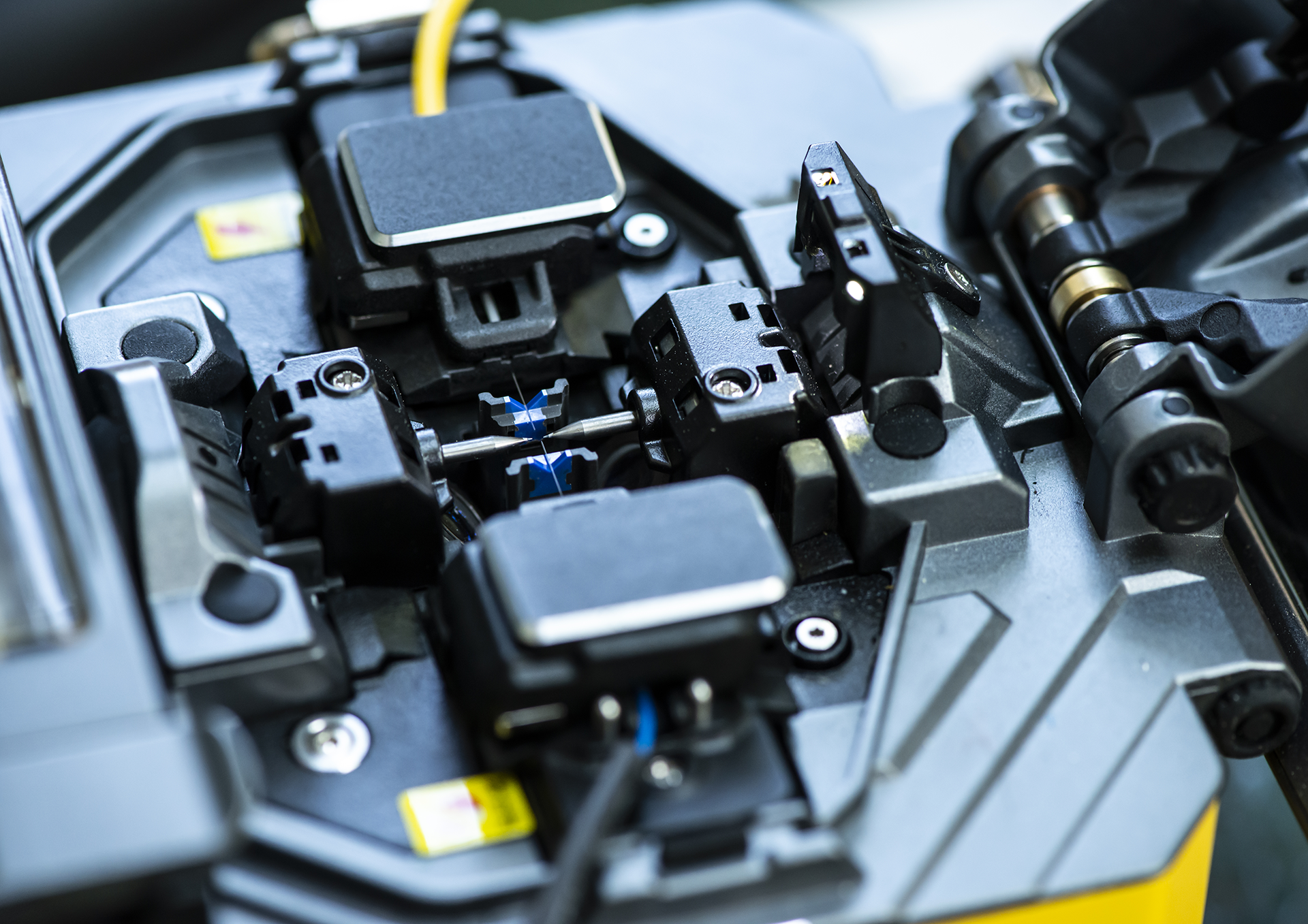

From aerospace avionics to medical devices, telecommunications, and advanced computing systems, high-tech electronics hardware lies at the heart of nearly every modern innovation. These devices are powered by intricate assemblies of housings, heat sinks, enclosures, and precision-fit components that must perform flawlessly under demanding conditions.

Producing these parts requires far more than just basic machining—it requires absolute accuracy, consistency, and an understanding of the unique materials and tolerances involved in electronics manufacturing. Trust Basin Precision Machining (BPM) to deliver unmatched value in manufacturing your complex components.

Why precision machining is essential for modern electronics

Electronics manufacturers face unique challenges that only a highly capable machine shop can address:

-

Micron-level tolerances – Electronic housings, connectors, and enclosures must fit together with extreme precision to ensure functionality, durability, and electromagnetic shielding.

-

Thermal management – Components such as heat sinks, thermal plates, and housings require machining for efficient heat dissipation.

-

Advanced materials – Aluminum alloys, copper, stainless steels, and specialty composites are commonly used in electronics hardware and require skilled machining expertise.

-

Miniaturization and complexity – As devices become smaller yet more powerful, machining must achieve tighter tolerances and more intricate geometries.

-

Reliability in the field – Electronics hardware is often exposed to vibrations, temperature extremes, and long duty cycles. Machined components must maintain performance under these stresses.

Without precision machining, even the most advanced electronic designs cannot move from concept to market.

Why electronics manufacturers choose BPM

We understand the pressures facing OEMs and Tier 1 manufacturers in the electronics industry. The allure of overseas machine shops has diminished with the creation of new tariffs and a renewed interest in American-made products. And when it comes to mission-critical avionics systems or intellectual property that needs to stay secure, you need a machining partner you know and trust.

Basin Precision Machining provides:

-

On-time delivery – Project delays can be catastrophic in fast-moving industries. BPM’s track record ensures your components arrive when you need them.

-

Low cost without compromise – Our lean processes, automation, and skilled workforce keep costs competitive while maintaining world-class quality.

-

Made-in-America quality – By sourcing locally, you reduce supply chain risks, support American jobs, and strengthen the domestic economy.

-

Scalable capacity – Whether you need prototype development or high-volume production, BPM has the technology and workforce to deliver.

Your next machine shop

High-tech electronics demand large-scale production with consistency, repeatability, and absolute accuracy. We combine advanced CNC technology, automated processes, and skilled American machinists to produce fine electronic components that you can trust to power your sophisticated products.

Contact us today to get started.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Location:

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003