Precision Machining for Factory Automation and Robotics

Modern factory automation and robotics: Powering America’s future

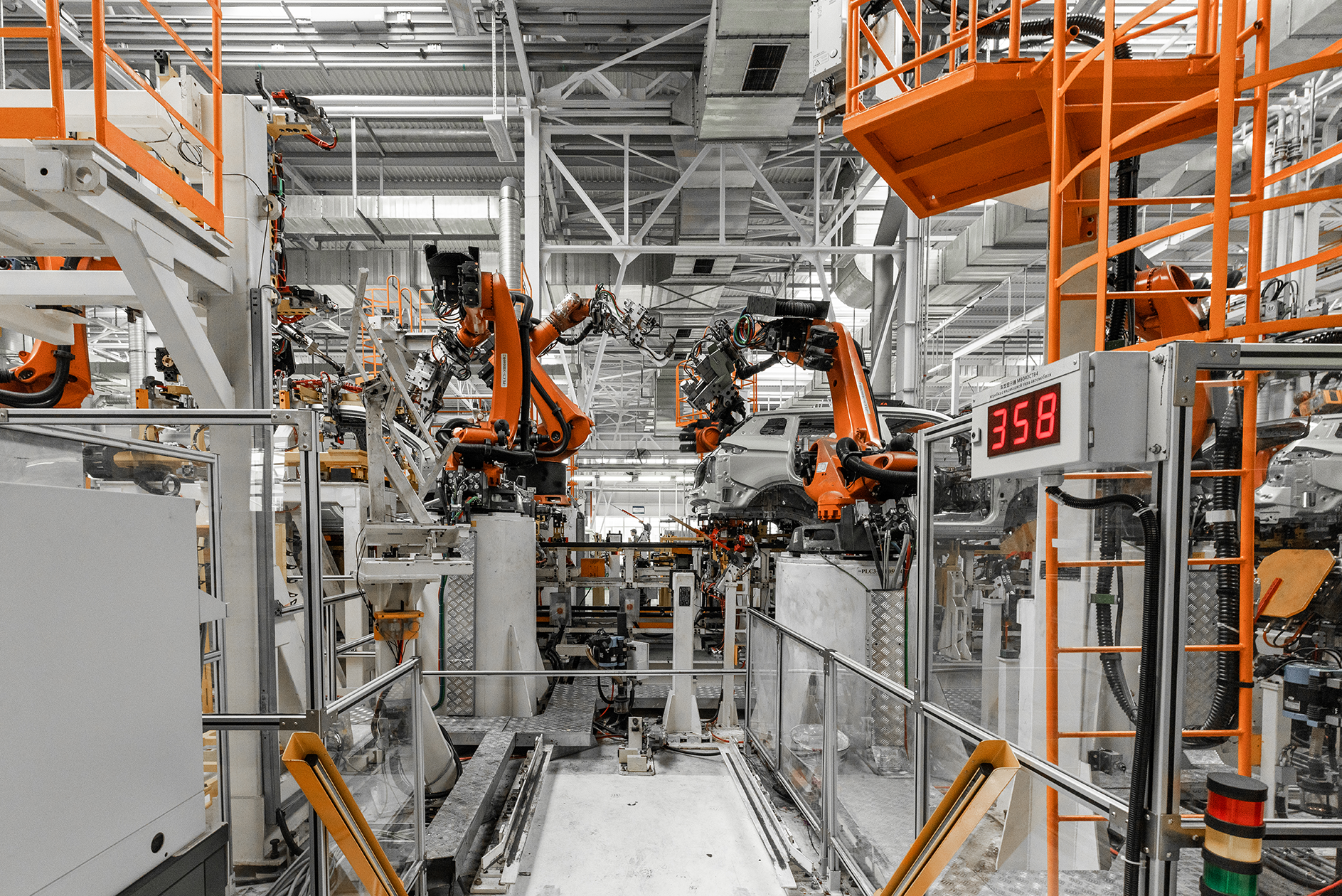

Modern factory automation and robotics are transforming the way the world manufactures. Automated systems drive efficiency, improve product quality, reduce costs, and allow companies to keep pace with rapidly changing global demand. From assembly lines and packaging to high-precision machining and advanced robotics, these technologies fuel innovation and set the standard for productivity in today’s economy.

In the United States, automation and robotics also mean something more: strengthening our industrial base, reshoring manufacturing, and creating sustainable American jobs. By building and supporting automation systems at home, American companies keep value within the local economy, promote self-reliance, and secure a stronger future for the workforce.

Why precision machining is critical to automation and robotics

Automation and robotics equipment demands components that are complex, reliable, and produced with extreme precision. Tight tolerances, intricate geometries, and robust materials all require a manufacturing partner who understands the stakes. That’s where Basin Precision Machining (BPM) delivers unmatched value.

Our state-of-the-art CNC machining centers and advanced quality control processes ensure every part we produce meets the highest industry standards. Whether it’s structural housings, gears, shafts, or specialized assemblies for robotic arms and automated factory systems, BPM provides the accuracy and repeatability that automation OEMs and Tier 1 manufacturers depend on.

The Basin Precision advantage

Choosing Basin Precision Machining means choosing:

-

Premier quality – Every component undergoes rigorous quality assurance to meet or exceed customer requirements.

-

On-time delivery – We understand the pace of modern manufacturing and pride ourselves on delivering parts when you need them.

-

Cost efficiency – Our lean processes and automation investments allow us to provide competitive pricing without compromising performance.

-

Made in America – By working with BPM, you’re not just buying components—you’re fueling American manufacturing, creating American jobs, and helping to build a stronger national economy.

Strengthening American industry together

Automation and robotics will define the next generation of manufacturing, but they rely on the foundation of world-class machining. Basin Precision Machining is proud to partner with automation and robotics companies who share our belief in American-made quality and innovation. Together, we can push the boundaries of technology while supporting the communities and workforce that make it all possible.

Contact us today to get started.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Location:

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003