Zeiss DuraMax Coordinate Measuring Machine (CMM): Compact Precision with Advanced Scanning Power

What is a Zeiss DuraMax coordinate measuring machine?

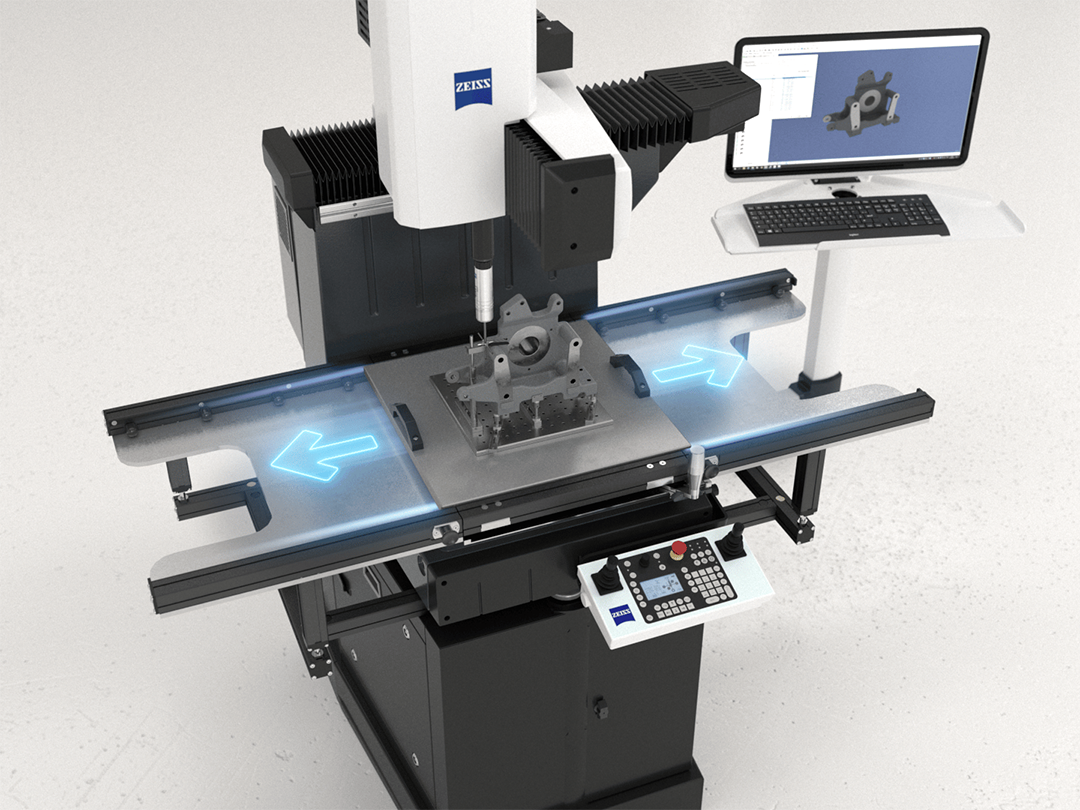

The Zeiss DuraMax is a compact coordinate measuring machine (CMM) designed for high-accuracy inspection directly on the shop floor. Built by Carl Zeiss, a global leader in metrology, the DuraMax delivers reliable 3D measurement data in environments where traditional CMMs might struggle.

Unlike larger CMM systems that require a climate-controlled lab, the Zeiss DuraMax is designed to operate in standard manufacturing conditions—making it ideal for in-process quality control.

The advantage of the VAST scanning head

Equipped with the Zeiss VAST scanning head, the DuraMax goes beyond simple point-to-point measurements. The VAST system uses continuous contact scanning, capturing hundreds or thousands of data points along a surface in a single pass.

This technology provides:

-

Higher accuracy – More data points mean better surface definition

-

Faster inspections – Full geometries measured in less time

-

Better repeatability – Reliable results across multiple runs and operators

-

Detailed reporting – Comprehensive dimensional analysis for every part

Why precision measurement matters

In modern manufacturing, precision isn’t just about meeting a drawing—it’s about guaranteeing functionality, safety, and performance. A part that is even a fraction of a millimeter out of tolerance can cause:

-

Assembly failures

-

Reduced product lifespan

-

Safety risks in critical applications

-

Increased scrap and rework costs

The Zeiss DuraMax with VAST scanning ensures that these issues are caught early, saving time, reducing waste, and protecting your brand’s reputation.

Why you should trust a machine shop with a Zeiss Contura

Choosing a CNC machine shop that operates a Zeiss DuraMax with VAST scanning head means you’re working with a partner that invests in state-of-the-art inspection technology and prioritizes your product’s quality.

Benefits include:

-

On-the-spot inspection – Measurements can be taken directly on the production floor

-

Micron-level accuracy – Essential for tight-tolerance machining

-

Shorter lead times – Faster inspections mean quicker project turnaround

-

Proof of compliance – Detailed CMM reports for quality assurance

Learn more

When you see a Zeiss DuraMax CMM with VAST scanning head on a shop floor, it’s more than just a machine—it’s a commitment to accuracy, efficiency, and quality assurance. It means every part you receive is measured against the highest standards, with data to prove it.

Contact us to learn more about our quality assurance equipment and processes.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

State-of-the-art

Our proprietary software, Total Tool Maintenance TM™ (TTM™), Automation in Manufacturing™ (AIM™), and Scheduling System provide the data and information we need to produce quality parts, on-time.

We are...

Working smarter, not just harder

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Innovative

- Our teams have the resources to meet customer needs.

- FMS automation reduces setups and maximizes utilization.

- Thermal deburring processes for 100% burr free product.

- Coordinate measuring machines and a fully networked facility help teams quickly gather relevant, accurate information

© 2025 Basin Precision Machining • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Jefferson, WI Location • Basin Precision Machining • 211 Collins Road • Jefferson, WI • 920-674-6003