Mazak Quick Turn CNC Machines

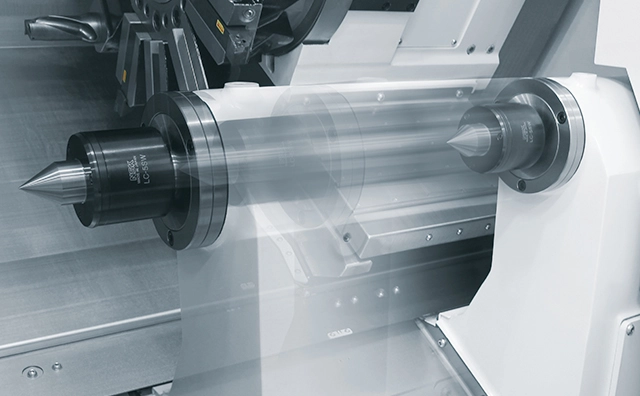

What is the Mazak Quick Turn Nexus CNC machine?

Mazak Quick Turn Nexus CNC turning centers bring together advanced technology, productivity and value to deliver exceptional performance.

Because these machines are available in a wide array of sizes and configurations, their capability varies widely as well.

At Basin Precision, we have three types of Mazak Quick Turn Nexus:

- QTN 200MS

- QTN 250MS

- QTN 250 200/500U

Features of the Mazak Quick Turn Nexus series

-

Built-in motor spindle: equipped on all models; can perform heavy-duty machining of difficult materials or ferrous metals, as well as high-speed machining of non-ferrous materials like aluminum.

-

High-rigidity: stable machining accuracy thanks to heavy-duty construction. The absence of gears and belts within the spindle minimizes vibration and improves surface accuracy.

-

Turning, milling, Y-axis and second spindle: the sophisticated nature of these machines allows for high-speed and high-accuracy machining of complex workpieces. Multi-tasking of large workpieces is also possible within these compact machines.

-

NC tailstock and steady rest: operator can move the NC tailstock to the correct position and set the optimal thrust force, supporting high-accuracy machining of shaft workpieces.

Benefits of the Mazak Quick Turn Nexus series of CNC machines

Consistent precision across every part

The Quick Turn Nexus delivers repeatable accuracy with minimal variation, allowing us to meet tight tolerances—even on complex profiles or threads.

Fast cycle times for shorter lead times

With rapid tool indexing and powerful axis drives, we can cut production times significantly, helping you get your parts when you need them.

Smooth surface finishes, less post-processing

The combination of rigid construction and high spindle speed ensures a clean cut, resulting in parts that often require no additional finishing work.

Versatile material handling

From stainless steel and aluminum to brass, plastics, and exotic alloys, this machine can handle a wide variety of materials without compromising quality.

Perfect for both short-run and production work

The Nexus’ flexible tooling and efficient setup make it ideal for one-off jobs, prototypes, and full production batches alike.

Learn more

Contact us to learn more about how the Mazak Quick Turn Nexus machines help us better serve our customers.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003