Precision Machining of Braking System Components

Precision braking components you can trust

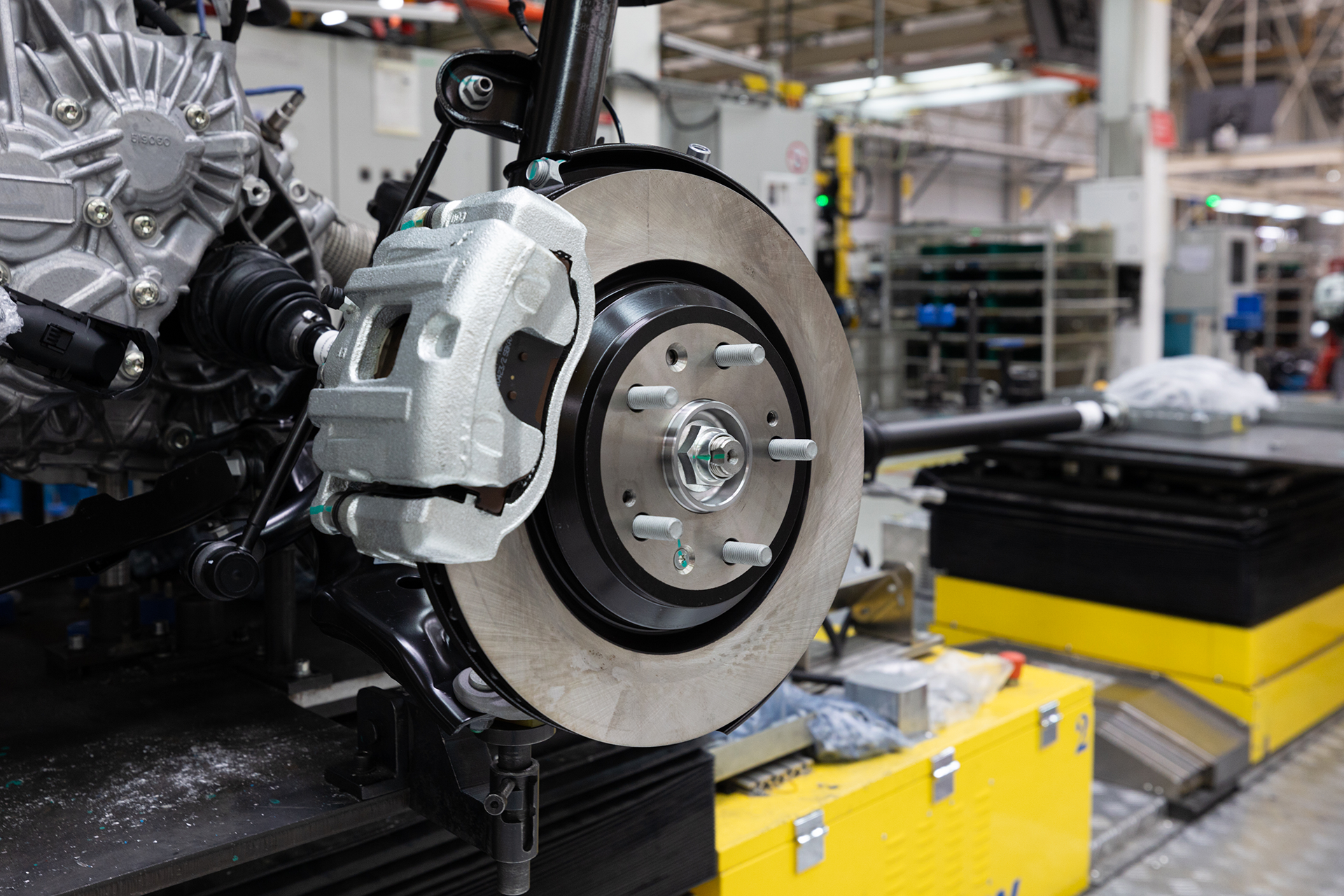

Braking systems are among the most critical safety features in any machine, whether it’s a passenger vehicle, industrial equipment—virtually anything moving that needs to be stopped.

The performance of these systems depends on the reliability and accuracy of their components. A fraction of a millimeter can make the difference between optimal stopping power and compromised safety. For this reason, manufacturers of braking systems must partner with a machine shop that has the expertise, technology, and quality systems to deliver consistent precision.

We specialize in producing braking components that meet the highest performance and safety requirements demanded by OEMs and Tier 1 suppliers.

Why braking components require advanced machining

Braking systems operate under high stress, extreme heat, and significant mechanical loads. To function reliably, every component must be manufactured to exact specifications and tolerances. Common braking components that demand advanced CNC machining include:

-

Brake caliper housings

-

Master cylinder bodies

-

Brake pistons

-

Anti-lock braking system (ABS) components

-

Rotor hubs and carriers

-

Custom braking parts for aerospace and industrial equipment

These parts require a combination of precision milling, turning, grinding, and sometimes specialized processes like honing or surface finishing to achieve the required performance.

The role of a sophisticated machine shop

Not all machine shops are capable of producing braking components that meet OEM and aerospace-level requirements. A sophisticated partner like Basin Precision Machining provides:

-

Advanced CNC equipment – 5-axis machining centers, high-precision grinders, and automated inspection systems to ensure accuracy. Learn more »

-

Tight tolerance expertise – delivering components that meet micron-level specifications critical to braking system reliability.

-

Material expertise – experience machining hardened steels, high-strength alloys, and specialty materials designed to withstand high stress and thermal conditions.

-

Quality assurance – ISO-certified quality systems, real-time inspection, and full traceability to guarantee compliance with customer and industry standards. Learn more »

Challenges in manufacturing braking components

Producing braking components presents several unique challenges:

-

Heat resistance – machining materials that can withstand high temperatures without deformation.

-

Complex geometries – precision machining of intricate designs for pistons, calipers, and ABS components.

-

Consistency at scale – maintaining repeatability across high production volumes while preserving tight tolerances.

-

Safety-critical performance – ensuring that every part performs flawlessly, since failures in braking systems are unacceptable.

At Basin Precision Machining, we meet these challenges with a combination of advanced equipment, skilled machinists, and robust quality control processes.

Why OEMs and Tier 1 suppliers trust Basin Precision Machining

For manufacturers of motor vehicles, heavy industrial equipment, and aerospace platforms, choosing a machining partner for braking components is not just about cost—it’s about trust, safety, and long-term performance. Basin Precision Machining has built a reputation for reliability, quality, and engineering support that helps our customers bring safer, more efficient braking systems to market.

When performance and safety are on the line, you need more than just a supplier—you need a partner with the technical expertise and commitment to quality that ensures your braking systems perform under the most demanding conditions.

Partner with a proven manufacturing specialist

If you are an OEM or Tier 1 manufacturer seeking a precision machining partner for critical braking components, Basin Precision Machining has the capabilities and experience you can count on. Our team is ready to support your project from prototype through production with a focus on safety, quality, and efficiency.

Contact Basin Precision Machining today to learn more about our precision machining services for braking components.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Location:

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003