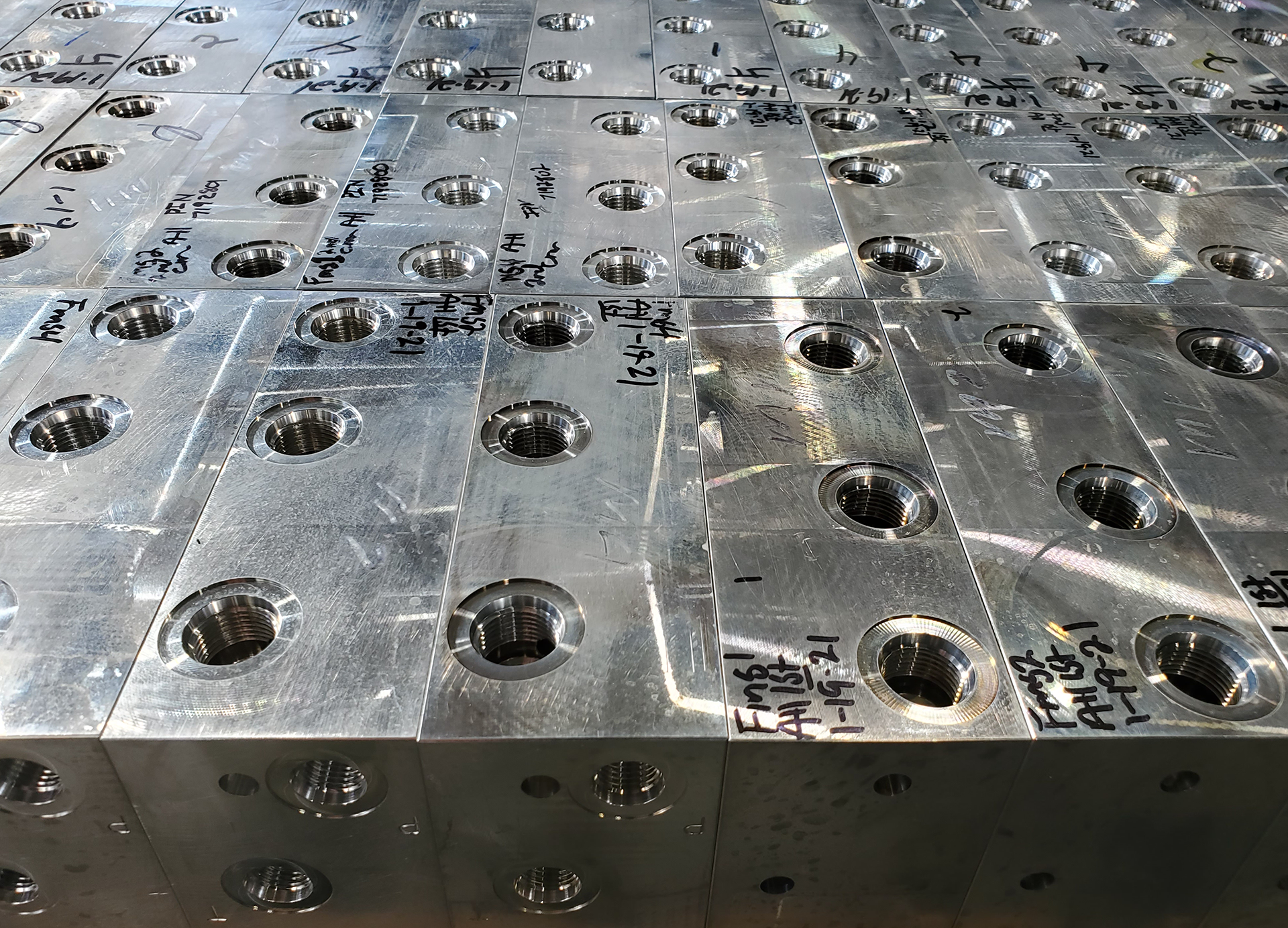

Precision CNC machining for OEMs and industry leaders

Since 1980, Basin Precision Machining has been a trusted American CNC machine shop specializing in high-volume, tight-tolerance machined components and assemblies. We partner with automotive manufacturers, oil and gas companies, agricultural equipment makers, aerospace suppliers, and other industrial OEMs to deliver precision parts that meet the most stringent specifications.

With over four decades of expertise, we provide reliable, cost-effective machining services that keep our customers competitive in demanding global markets.

American manufacturing, built for performance

At Basin Precision Machining, we combine skilled American machinists with advanced CNC technology to produce high-quality OEM components. Our focus on Excellence, Teamwork, Integrity, Continuous Improvement, and Grit ensures we deliver superior results on every project.

Whether you need precision automotive parts, custom aerospace components, oilfield equipment parts, or agricultural machinery assemblies, we deliver repeatable quality and dependable lead times.

Automated CNC machining for maximum efficiency

Our state-of-the-art CNC equipment enables us to produce complex components from high-performance materials in a single setup, reducing cycle times and improving accuracy. We specialize in multi-axis CNC milling, CNC turning, and precision grinding, serving industries that demand tight tolerances and consistent quality.

Basin Precision Machining offers:

-

Design for manufacturability (DFM) to optimize performance and reduce cost

-

Cradle-to-grave production management for OEM programs

-

ISO 9001:2015 certified processes for zero-defect manufacturing

-

Reliable supply chain partnerships for consistent material availability

From oil and gas drilling equipment components to aerospace structural parts and agriculture drive system assemblies, we have the experience and automation capabilities to deliver industry-leading precision.

Read more about our dedication to quality »

Partner with a proven OEM machining supplier

Basin Precision Machining is more than just a vendor—we are a strategic manufacturing partner. Our high-volume CNC machining capabilities, commitment to quality, and deep industry knowledge help customers achieve better performance, lower production costs, and faster speed-to-market.

Contact us today to discuss your precision machining needs and see why leading OEMs across automotive, oil & gas, agriculture, aerospace, and industrial manufacturing trust Basin Precision Machining.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Location:

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003