Quality machining begins with quality process

Continuously improving, continuously adapting to a world of change

Like the global economy, the manufacturing landscape is never static. International trade agreements shift supply chains, economic conditions drive cost pressures and technology continues to evolve at a relentless pace. Machine shops cannot afford to remain fixed in their ways—they must continuously improve and adapt to stay competitive and meet the needs of OEMs and Tier 1 manufacturers.

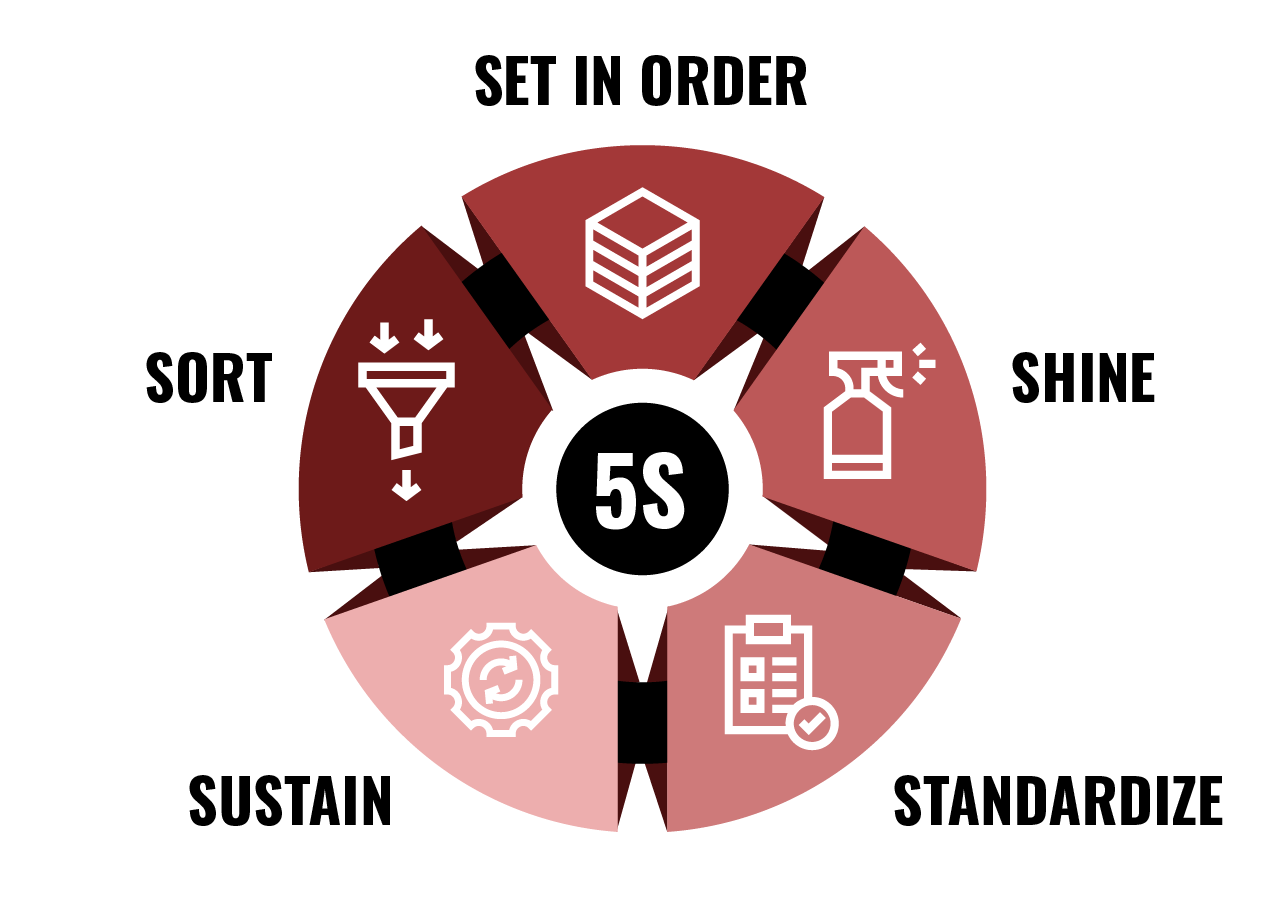

Our dedication to the “5S methodology” (sort, set in order, shine, standardize, sustain) keeps our shop lean, flexible, and responsive. By embedding these principles into daily operations, we eliminate waste, enforce consistent workplace practices and maintain a disciplined foundation that allows us to pivot quickly as customer requirements grow and evolve. We also keep our workers safe and at their best.

Thanks to our culture of continuous improvement and lean manufacturing, we provide our customers with the highest standards of quality and keep pace with the changing demands of today’s global market.

What 5S looks like in a modern shop

5S is more than tidiness; it’s the daily discipline that stabilizes processes and reveals problems early. The five pillars of the 5S methodology are: Sort, Set in order, Shine, Standardize, Sustain.

Partnership with MoffittXL

To accelerate results, we work with MoffittXL, a team of lean-management consultants with a reputation for building continuous-improvement systems that optimize operations and scale performance. Their frameworks help us reduce waste, enforce consistent workplace practices, and “run to demand” through takt-time alignment so capacity and customer need stay in sync.

MoffittXL’s playbook emphasizes one-piece flow, pull systems, visual controls, and 5S—core building blocks that create accountability on the floor and measurable gains in throughput and quality.

Working to takt time for reliable delivery

Takt time (available production time divided by customer demand) sets the rhythm for each cell. We design capacity, staffing, and buffer strategy around that “heartbeat” to enable one-piece flow. This curbs overproduction, stabilizes queues, and helps us promise realistic, repeatable lead times.

With MoffittXL’s guidance, we align routings and resource plans to takt, implement point-of-use kanban, and reduce changeover pain (SMED) so smaller batches still make business sense. This lowers WIP and increases on-time performance.

What does this mean for you?

-

First-time quality: Stable setups, controlled tooling, and in-process inspection embedded in standard work reduce variation and rework.

-

Shorter, steadier lead times: Flow to takt and pull signals keeps queues under control—even as mix and demand shift.

-

Fewer surprises: Visual management and layered audits surface issues fast so corrective action can be taken before it affects you.

-

Launch with confidence: Robust 5S and standardized methods translate cleanly from prototypes to PPAP to volume.

-

Lower total cost: Waste exits the system—fewer expedites, less scrap, less inventory, and maximized spindle utilization.

Whether you’re an OEM ramping a new platform or a Tier 1 supplier consolidating your vendor base, Basin Precision Machining offers the rigor of 5S, the cadence of takt-time flow, and the momentum of continuous improvement—backed by MoffittXL’s proven systems. Let’s put that to work on your parts and your timelines. Contact us today to get started.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003