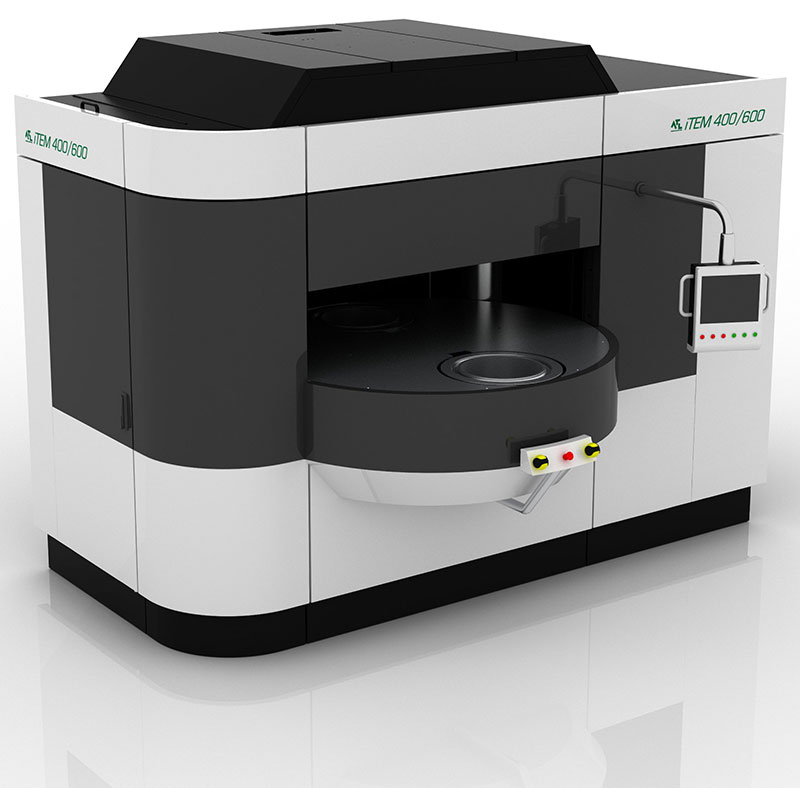

ATL iTEM 400/600 Thermal Deburring System

What is the ATL iTEM 400/600 thermal deburring system?

The ATL iTEM 400/600 is an industrial thermal energy deburring machine (TEM) designed to remove burrs, flash and tiny residues from machined and cast parts using a controlled, high-energy gas combustion inside a sealed chamber. Parts are placed in the chamber, a combustible gas–oxygen mix is introduced and ignited, and the brief, intense thermal pulse vaporizes and oxidizes burrs while leaving the bulk of the workpiece intact. The iTEM 400/600 is built to handle relatively large parts (chamber Ø 400 x H 600 mm) and is offered with multi-station tables, safety systems and PLC controls for repeatable batch production.

How does thermal deburring work?

Step 1) Parts are fixtured in the chamber (can be a full load of many small parts or individual large pieces).

Step 2) The chamber is filled with a precise mixture of fuel (e.g., methane/hydrogen) and oxygen at controlled pressure.

Step 3) Ignition produces a very short, high-energy combustion pulse that oxidizes and vaporizes burrs — especially at thin, sharp features, internal intersections and crevices.

Step 4) The chamber vents and parts are cleaned of residual oxides (often with a brief wash or blow-off).

The process is fast (single-shot cycles measured in seconds to a few minutes depending on configuration) and designed to reach internal burrs and features impossible to access with mechanical methods.

For a more complete explanation of the thermal deburring process, watch the video below.

Why is thermal deburring beneficial to CNC machining?

Reach and completeness

Thermal deburring removes burrs from blind holes, intersecting bores, threads and other internal geometries that mechanical or hand deburring frequently miss. This yields consistently burr-free components straight from the process.

Speed and cycle-time reduction

A batch cycle can deburr dozens (or hundreds) of small parts or finish a single large part in a single operation, cutting hours of manual labor and reducing lead time.

Non-contact, low distortion

Because the process does not mechanically contact the part, there’s minimal risk of altering critical dimensions, warping thin walls, or damaging delicate features compared with abrasive or mechanical methods.

Cleaner, FOD-free outcomes

The high-energy pulse vaporizes chips and foreign object debris that might be trapped in features—reducing potential foreign object debris (FOD) and improving cleanliness for hydraulic, pneumatic and aerospace parts.

Versatility of materials

Thermal deburring is used successfully on steels, stainless steels, aluminum, brass, zinc die castings and many thermoplastics—making it useful across varied CNC applications from automotive to hydraulics.

Practical advantages of thermal deburring for manufacturers and their customers

Better first-pass yield

Fewer rejected parts or rework because micro-burrs and hard-to-see burrs are reliably removed.

Predictable quality and traceability

PLC control, documented cycles and repeatable results let shops meet tighter tolerances and quality standards.

Lower labor cost and faster throughput

Manual deburring is time-consuming and inconsistent; thermal deburring automates the finishing step and frees skilled operators for higher-value tasks.

Improved part performance and lifecycle

Burrs can cause assembly issues, fluid leaks, uneven sealing or premature wear; fully deburred parts perform more reliably in the field.

Why choose a machine shop that has an ATL iTEM 400/600?

Consistent, burr-free parts

Shops with iTEM systems deliver parts that meet higher cleanliness and edge-quality expectations—especially important for hydraulic manifolds, valves, and precision assemblies.

Faster lead times on complex parts

The iTEM’s large chamber and fast cycles let shops batch finish parts quickly without tying up expensive CNC machines or hand-finishing work.

Broader material and geometry capability

Having thermal deburring in-house means a shop can accept work that would otherwise require outsourced finishing or more costly secondary processes.

Compliance and safety

Reputable ATL systems include industrial safety features, ATEX/CE compliance and gas-monitoring for safe operation—a must when working with combustible gas processes.

Typical thermal deburring use cases

-

Hydraulic and pneumatic manifolds and valves (many internal cross-bores and intersecting features).

-

Automotive and powertrain components with complex bores and small features.

-

Aerospace parts where burrs are unacceptable and cleanliness is critical.

-

Die-cast components (zinc, aluminum) where flash and machining burrs can be removed in the same cycle.

Thermal deburring limitations and complementary processes

-

Surface finish polishing and very fine cosmetic finishes may still need secondary polishing or blasting after thermal deburring.

-

Extremely thick, robust burrs created by heavy cutting may benefit from preliminary mechanical trimming before thermal deburring. If the burrs are too large, the iTEM will melt them on to the surface instead of removing them.

-

Thermal deburring causes surface oxidation on the smallest scale; to combat this, we send our parts through a light cleaning/washing step after processing (see photo below).

Frequently asked questions about thermal deburring

Will thermal deburring damage my part’s dimensions?

No—thermal deburring is a non-contact process that vaporizes burrs and thin fins while leaving the part’s bulk geometry intact. That said, critical thin features should be evaluated in advance.

What materials are compatible?

Steel, stainless steel, aluminum, brass, zinc die casting and many thermoplastics are commonly processed. Some alloys and special-use plastics should be tested first.

How fast is a cycle?

Cycle times depend on charge size and machine configuration. For iTEM 400/600 configurations, single-shot cycles for a full charge are measured in seconds to a few minutes; multi-shot or special processes take longer.

Learn more

If your part’s performance, cleanliness and consistent edge quality matter—and especially if your components contain internal bores, intersecting holes or delicate features—our ATL iTEM 400/600 can deliver faster, more reliable, and more cost-effective finishing than manual or purely mechanical deburring alone. The result: improved first-pass yield, shorter lead times, and parts that meet the standards your assemblies require.

Contact us to learn more about our quality assurance equipment and processes.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003