Okuma MB-5000H HMC

What is the Okuma MB-5000H HMC system?

To meet the evolving needs of today’s industries, we’ve invested in the Okuma MB-5000H, a state-of-the-art 4-axis horizontal machining center (HMC) designed for rapid, accurate, and lights-out production.

The MB-5000H allows us to take on complex parts, high volumes and tight tolerances with a larger pallet size and table load capacity than our MB-4000H.

Features of the Makino a51e HMC system

500mm pallet horizontal machining

- Versatile for mid-sized parts across a wide range of materials.

- Ideal for components that require multiple operations and critical tolerances.

Full 4-axis capability (B-axis rotation)

- Enables multi-face machining in one setup.

- Reduces fixture changes, handling time, and geometric inaccuracy.

High-speed spindle

- Up to 15,000 RPM with strong torque for both roughing and finishing.

- Excellent performance in aluminum, steel, and exotic alloys.

Automatic pallet changer (dual pallet system)

- Load/unload parts while the machine runs.

- Significantly reduces downtime and increases throughput.

OSP-P300M control system

- Okuma’s intelligent CNC controller offers simplified programming, live monitoring, and superior integration.

- Supports full G-code and conversational programming.

Thermo-friendly construction

- Built-in thermal stability maintains tight tolerances over long production cycles.

- Ideal for demanding aerospace, medical, and high-precision industrial applications.

Benefits of the Okuma MB-5000H HMC system

Fast, reliable turnaround

With dual-pallet automation and a high-speed spindle, we can produce parts faster and keep delivery times short—even on complex jobs.

Tight tolerances, every time

Rigid construction, thermal control, and smart technology mean we consistently hold tolerances to the micron level.

Efficient, multi-side machining

The 4-axis capability allows us to complete more work in one setup, reducing both time and error from re-clamping.

Lights-out manufacturing

Our MB-5000H is built for 24/7 productivity, allowing us to run parts unattended overnight. This maximizes output and lowers costs—benefits we pass on to our customers.

Lower costs through smarter machining

By reducing idle time, minimizing setups, and increasing throughput, we can offer premium machining services at competitive prices.

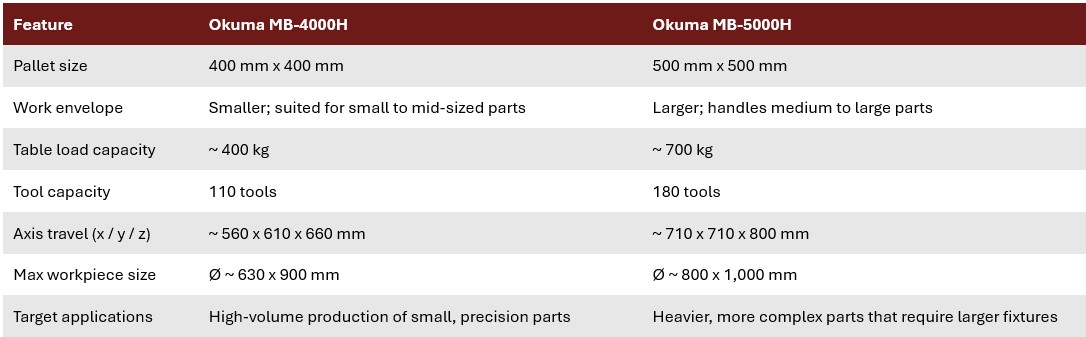

How does the Okuma MB-5000H compare to the MB-4000H?

The Okuma MB-4000H and Okuma MB-5000H are both high-performance 4-axis horizontal machining centers (HMCs) designed for productivity, precision, and automation. However, they are built for slightly different part sizes and production needs.

Here’s a breakdown of their key differences:

Learn more

Contact us to learn more about how the Okuma MB-5000H HMC system helps us better serve our customers.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003