Okuma MB-4000H HMC

What is the Okuma MB-4000H HMC system?

The Okuma MB-4000H is one of the most advanced and reliable horizontal machining centers (HMC) in the industry. Built for high-speed, high-accuracy and high-efficiency machining, this HMC allows us to meet the strictest tolerances and deliver parts faster than ever before.

Features of the Okuma MB-4000H HMC system

400mm pallet horizontal machining center

- Ideal for small to mid-sized parts with tight tolerance requirements.

- Compact footprint without sacrificing power or rigidity.

4-axis capability with full b-axis rotation

- Enables multi-sided machining in a single setup.

- Reduces the need for re-clamping, improving accuracy and cycle times.

High-speed spindle performance

- Up to 15,000 RPM spindle for high-speed, precision cutting.

- Built-in thermal compensation ensures dimensional stability.

Dual-pallet changer system

- Reduces idle time between parts.

- Allows operators to load and unload without interrupting machining.

OSP-P300MA control system

- Okuma’s proprietary control platform integrates machine, CNC, and drive functions into one.

- Fast, user-friendly programming with real-time monitoring and diagnostics.

Thermo-friendly design & collision avoidance

- Maintains accuracy over long runs and varying shop temperatures.

- Built-in safety systems prevent tool or spindle crashes.

Benefits of the Okuma MB-4000H HMC system

Faster turnaround times

With high spindle speeds, dual pallets, and 4-axis flexibility, we cut cycle times and accelerate delivery schedules.

Superior accuracy

Thermal compensation and rigid construction allow us to maintain microns of tolerance—even in high-volume production.

Less handling, more consistency

Multi-face machining in one setup reduces human error, setup time, and dimensional variability.

Lights-out ready

The MB-4000H’s automation capabilities allow for unattended machining, enabling us to run jobs overnight and increase output without added labor costs.

More efficiency, lower costs

Our investment in automation and technology helps us offer competitive pricing without compromising on quality.

How does the Okuma MB-4000H compare to the MB-5000H?

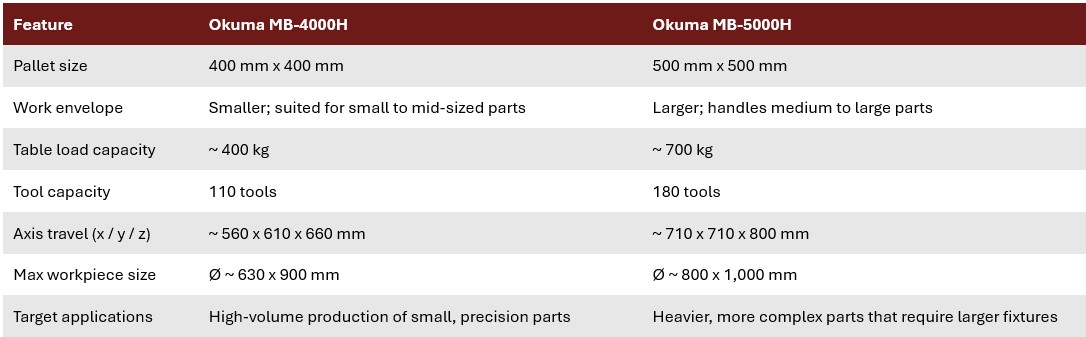

The Okuma MB-4000H and Okuma MB-5000H are both high-performance 4-axis horizontal machining centers (HMCs) designed for productivity, precision, and automation. However, they are built for slightly different part sizes and production needs.

Here’s a breakdown of their key differences:

Learn more

Contact us to learn more about how the Okuma MB-4000H HMC system helps us better serve our customers.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We are...

Proudly American

Basin Precision Machining is proudly American, built on the values of hard work, grit, and a commitment to excellence that this country was founded on. Every component we produce is a testament to American craftsmanship and resilience, and we stand tall knowing that when manufacturers choose to work with us, they’re choosing to keep manufacturing strong right here at home in the USA.

We are...

Working smarter

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We are...

Committed to you

Customer satisfaction is at the heart of everything we do. We work closely with clients to understand their needs, deliver precision parts on time and maintain the highest quality standards. Our dedication to continuous improvement, responsive communication and reliable performance ensures that every project meets, or exceeds, expectations and works toward lasting partnerships grounded in trust and proven results.

© 2025 Basin Industries LLC • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Basin Precision Machining | 211 Collins Road | Jefferson, WI | 920-674-6003