Facilities

Basin Precision Machining Equipment List

Facility Size: 60,000 square feet. Climate controlled.

Employees/Shifts: 120+

FMS Systems

(1) – Mazak High Rise – Six 500MM 4-axis HMC’s, 4-axis, 120 Pallets, 2088 tools, RFID Tool Tracking, 1000PSI Coolant, Probing

(1) – Mazak 6 Pallet – 800MM 4-axis HMC – 48″ X 48″ X 48″, 4-axis, 6 pallets, 348 Tools, RFID Tool Tracking, 1160 lb/ft Spindle, 1000PSI 16GPM Coolant, Probing

(1) – Makino a51e HMCs 3 machines with 1969 IPM Rapids, 40 RPM 4th Axis Table, with a Makino MMC Multi Pallet Work Distribution System with 12 pallet stocker.

(1)– Makino A55E HMCs 3 machines with 3700 IPM Rapids, 40 RPM 4th Axis Table, with a Makino MMC Multi Pallet Work Distribution System with 12 pallet stocker.

Horizontal Machining Centers

(3) – MAZAK – Nexus 5000 -11 HMCs, each with 120 tool capacity, 2362 IPM Rapid, 12,000 RPM high torque, 40 HP 4th Axis Table, 2.7 second chip to chip tool change, 1000 PSI Filtered Coolant System.

(3) – Mazak HCN5000 – 500MM 4-axis HMC – 24″ X 24″ X 39″ – 10% 90% 100% 110 tools, 1000PSI Coolant, Probing.

(4) – OKUMA – MB 4000H HMCs, each with110 tool capacity, 2362 IPM Rapid 15,000 RPM, 35 HP VAC Spindle, 4th AXIS Table, 2.3 second chip to chip tool change, 1000 PSI Filtered Coolant System.

(3) – OKUMA – MB 5000H HMCs, each with up to180 tool capacity, 2362 IPM Rapid 15,000 RPM, 35 HP VAC Spindle, 4th AXIS Table, 2.3 second chip to chip tool change, 1000 PSI Filtered Coolant System.

(3) – Okuma MB4000 – 400MM 4-axis HMC 20″ X 20″ X 30″ 10% 90% 100% 110 tools, 1000PSI Coolant, Probing.

(4) – Makino 4 Axis a51e stand-alone HMCs , each with 1969 IPM Rapids, 40 RPM Table, 7 Second Tool Change, 1000 PSI Filtered Coolant System.

Vertical Machining Centers

(1) – Mazak QM 410 VMC, Smart 4l0A, 16” x 22” x 20” Travel, Mazatrol Smart Control, 4th Axis Rotary Trunion.

(1) – Mori Seiki GV503 VMCs, High Speed with 1900 IPM rapid, 12,000 RPM Spindle, 1000 PSI Coolant, Rotary Pallet changer, 29” x 25” x 22” Travel.

(1) – Haas DT-1 with 20? x 16? x 15.5? travel, Probe, 1200 IPM, 1.5 seconds Chip to Chip tool change, 15 Horsepower.

CNC Turning Centers

(4) – Mazak Turn Smart 250 20?/500U Universal 2 Axis CNC lathe, Max Chuck 10”, Max Turn Diam. 14.96”, Max. Length 19.55” with Mazatrol Smart Control, MT Connect software to support user macro.

(4) – Mazak QTP 100 CNC Lathes with High Pressure coolant.

(2) – Mazak QT 200MS CNC Lathes with Live Tooling, Sub-Spindle, and High-Pressure Coolant

(1) – Mazak QT 250MS CNC Lathe with Live Tooling, Sub-Spindle, and High-Pressure Coolant

(3) – Mori-Seiki Dura Turn 2050MC, MSX-504 III Control, Integrated Mill/Turn Centers, 4,000 RPM (18 HP) Spindle Motor, 2.5? Bar Capacity, 7.5HP, 6000 RPM Rotary Tool Milling Capability. Max. Chuck Diam. 10” Max Turn Diam. 13.3”, Max Length 22.4”

2 CNC Gear Hobs

(1) – Pfauter PE-80 CNC Gear Hob

(1) – GHO M200 CNC Gear Hob

(2) Colonial Table Up Vertical Broaches

Inspection

(3) Zeiss Contura CMM’s with VAST scanning head – Up to 78″ X 39″ X 24″ Capacity, probe racks and indexing heads

(4) Ziess DuraMax Shop Hardened CMM’s with passive VAST scanning head – 24″ X 20″ X 15″

(1) MicroVu Front Illuminated Optical Comparator

(1) ULM Super Micrometer for in house Gage Calibration

20,000+ Hand Gages

Additional Capabilities

PLEX Online Software provides enterprise resource planning (ERP) and a manufacturing execution system (MES), efficiently integrating departments and information across the organization. PLEX provides transparent Document Control, Engineering and Quality APQP, FMEA and dynamic control plans for inspection tracking, SPC, and Barcode Traceability.

BPM Engineering employs the recognized standards in modern programming, Solidworks for CAD, and Mastercam for CAM.

Deburring

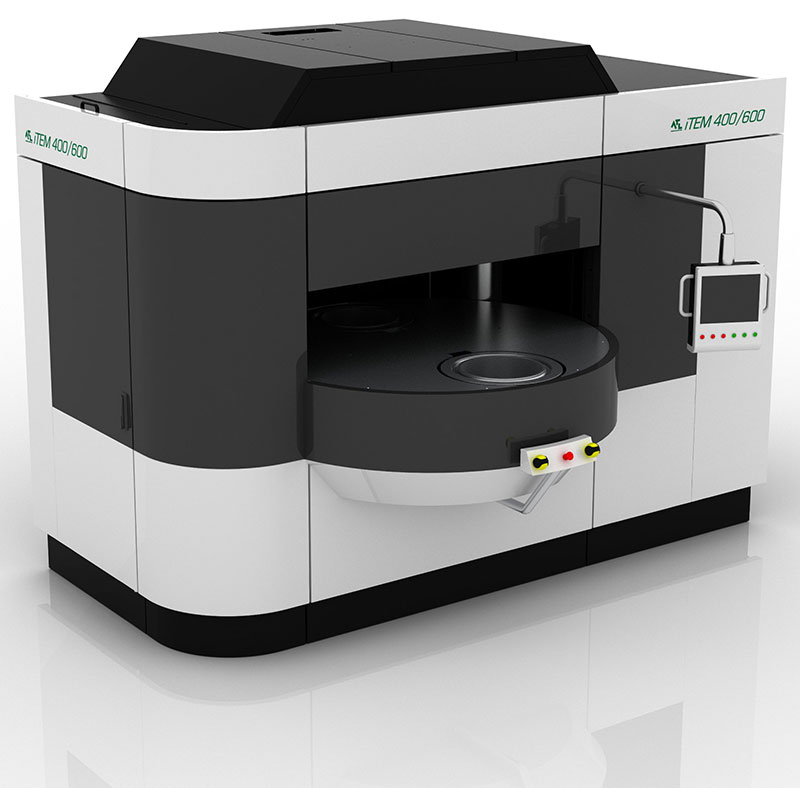

(1) ATL iTEM 400/600 Thermal Deburring System – 15″ Dia, 23″ Length – Twin Pot, dual shot Thermal Deburring System, first of its kind in the USA.

In Shop Capabilities for Production Sawing, Washing & Vibratory Deburring, Zoller Venturion CNC Tool Presetter/Measurement Machines.

Industries Served:

Defense • Motorcycle • Hydraulic Components • Agriculture • Aerospace • Heavy Equipment

Locations:

Jefferson, WI Location

211 Collins Road

Jefferson, WI

920-674-6003

Your Solutions

We Are...

State-of-the-art

Our proprietary software, Total Tool Maintenance TM™ (TTM™), Automation in Manufacturing™ (AIM™), and Scheduling System provide the data and information we need to produce quality parts, on-time.

We Are...

Working smarter, not just harder

Our Horizontal Machining Center capacity has been expanded with the addition of a Mazak Palletech Flexible Manufacturing System (FMS). One of the largest in the country, our system offers 6 500MM Horizontal Machining Centers, 120 pallets, and 348 tools per machine. We can now produce any mix of complex parts with zero setup.

We Are...

Innovative

- Our teams have the resources to meet customer needs.

- FMS automation reduces setups and maximizes utilization.

- Thermal deburring processes for 100% burr free product.

- Coordinate measuring machines and a fully networked facility help teams quickly gather relevant, accurate information

© 2023 Basin Precision Machining • Privacy Statement • Terms of Use • Site Design: D2P Web Design

Jefferson, WI Location • Basin Precision Machining • 211 Collins Road • Jefferson, WI • 920-674-6003